Hazard and Operability Study: Difference between revisions

imported>Milton Beychok m (Null edit to jog) |

mNo edit summary |

||

| (4 intermediate revisions by 3 users not shown) | |||

| Line 1: | Line 1: | ||

{{subpages}} | {{PropDel}}<br><br>{{subpages}} | ||

{{Image|Delek Refinery.jpg|right|350px|Fire at Delek Refinery in November 2008, Tyler, Texas}} | |||

{{TOC|right}} | {{TOC|right}} | ||

A '''Hazard and Operability Study''' (HAZOP) is a simple, structured methodology for identifying, evaluating and prioritizing potential hazardous occurrences in an existing process facility or a proposed new facility.<ref name=CCPS- | |||

A '''Hazard and Operability Study''' (HAZOP) is a simple, structured methodology for identifying, evaluating and prioritizing potential hazardous occurrences in an existing process facility or a proposed new facility.<ref name=CCPS-HazardEvaluation>{{cite book|author=Center for Chemical Process Safety (CCPS), AIChE|title=Guidelines for Hazard Evaluation Procedures|edition=3rd Edition|publisher=Wiley-[[American Institute of Chemical Engineers]]|year=2008|id=ISBN 0-471-97815-9}}</ref><ref name=Kletz>{{cite book|author=Trevor Kletz|title=Hazop and Hazan|edition=4th Edition|publisher=[[Institution of Chemical Engineers]]|year=2006|id=ISBN 0-85295-506-5}}</ref><ref>[http://www.lihoutech.com/hazop.htm Hazard & Operability Studies (HAZOPS)] Excellent explanation of HAZOPs by a HAZOP software company</ref> The HAZOP methodology is a safety analysis that uses and encourages imaginative thinking (or ''brainstorming'') and was first developed by [[Imperial Chemical Industries]] (ICI), a [[Britain|British]] chemical company. It is performed by a multi-disciplinary HAZOP team and entails the use of ''guide words'' to stimulate the ''brainstorming''. For a proposed new process facility (such as a [[Petroleum refining processes|petroleum refinery]], [[Natural gas processing|natural gas processing plant]] or [[chemical plant]]), a HAZOP may require many weeks to perform. | |||

Although the HAZOP methodology was originally developed to study chemical process facilities, it has been extended to other types of facilities and complex operations. | Although the HAZOP methodology was originally developed to study chemical process facilities, it has been extended to other types of facilities and complex operations. | ||

There are many other hazard evaluation (HE) techniques, some of which are simpler than a HAZOP and some of which are more complex. For example, the ''Checklist'' and ''What-If'' methodologies are simpler than a HAZOP, and the ''Failure Mode Effects and Analysis (FMEA)'' and ''Fault Tree'' methodologies are more complex. In the [[United States]] as well as some other nations, governmental regulations require some type of hazard evaluation be performed for certain, specified types of existing or proposed new process facilities. | There are many other hazard evaluation (HE) techniques, some of which are simpler than a HAZOP and some of which are more complex. For example, the ''Checklist'' and ''What-If'' methodologies are simpler than a HAZOP, and the ''Failure Mode Effects and Analysis (FMEA)'' and ''Fault Tree'' methodologies are more complex.<ref>All of these hazard evaluation methods are defined in Chapter 5 of the CCPS book named in reference 1</ref> In the [[United States of America]] as well as some other nations, governmental regulations require some type of hazard evaluation be performed for certain, specified types of existing or proposed new process facilities. | ||

==What a HAZOP is not== | ==What a HAZOP is not== | ||

| Line 194: | Line 196: | ||

==References== | ==References== | ||

{{reflist}} | {{reflist}}[[Category:Suggestion Bot Tag]] | ||

Latest revision as of 11:00, 26 August 2024

| This article may be deleted soon. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

A Hazard and Operability Study (HAZOP) is a simple, structured methodology for identifying, evaluating and prioritizing potential hazardous occurrences in an existing process facility or a proposed new facility.[1][2][3] The HAZOP methodology is a safety analysis that uses and encourages imaginative thinking (or brainstorming) and was first developed by Imperial Chemical Industries (ICI), a British chemical company. It is performed by a multi-disciplinary HAZOP team and entails the use of guide words to stimulate the brainstorming. For a proposed new process facility (such as a petroleum refinery, natural gas processing plant or chemical plant), a HAZOP may require many weeks to perform. Although the HAZOP methodology was originally developed to study chemical process facilities, it has been extended to other types of facilities and complex operations. There are many other hazard evaluation (HE) techniques, some of which are simpler than a HAZOP and some of which are more complex. For example, the Checklist and What-If methodologies are simpler than a HAZOP, and the Failure Mode Effects and Analysis (FMEA) and Fault Tree methodologies are more complex.[4] In the United States of America as well as some other nations, governmental regulations require some type of hazard evaluation be performed for certain, specified types of existing or proposed new process facilities. What a HAZOP is notA HAZOP is not an method to determine how far one can go in physically removing or mitigating all risks nor is it a method for defining detailed engineering or procedural solutions for eliminating sources of risk.[5] Most importantly, it is not a guarantee that adverse consequences will not occur. TerminologyTable 1 provides a list of the terms pertinent to a HAZOP along with their definitions:

Matrix of guide words and process parametersTable 2 presents an example matrix of which typical guide words are applicable to each of a typical set of process parameters:[5][6][7][8]

As noted, the above Table 1 is merely a typical example. The HAZOP team will select the appropriate sets of guide words and process parameters that are to be used for the process or operation being studied. The HAZOP teamThe team that will perform the HAZOP should consist of personnel with a good understanding of the process facility to be studied. The team members should be people from a range of disciplines and that is one of the strengths of the HAZOP methodology.[9] A HAZOP team typically meets daily for sessions of 3 to 6 hours each and, as noted above, it may require many weeks to perform the HAZOP. A typical team should be limited to no more than about 8 to 9 members and include: A team leader: It is important that the team leader be someone from outside the immediate organization of the facility being analyzed and, ideally, come from a completely independent company. The leader should be experienced in the HAZOP methodology and have in-depth knowledge of how chemical process facilities work even though he or she may not have an intimate knowledge of the technology involved in the particular facility being studied. A scribe or recorder: The primary function of the scribe is to record and document the proceeding of the HAZOP sessions as well as any recommendations made by the team. Process designer (s): One or more representative(s) of the team that designed the facility to explain the process design and provide other information that may be needed. If the process design of the facility involved an outside contractor or process licensor, then they should provide a knowledgeable process design representative. Facility operator: A representative of the workers selected to operate the facility. Process control expert: A process control expert to provide expertise on the instruments and control systems, as well as the safety shutdown systems. He or she should be a full-time member of the team. Maintenance representative: If appropriate, the team should include a representative of the facility's maintenance department. Specialist (s): At times, specialists may be needed for limited time periods. For example, if the team is studying some issues involving corrosion, it may need the help of a corrosion expert for that part of the HAZOP. Pre-HAZOP preparationsBefore the HAZOP commences, the team leader should:

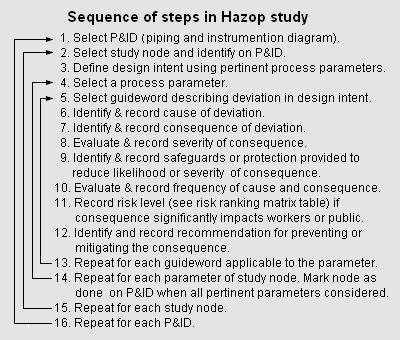

MethodologyAs shown in the adjacent Figure 1, the sequence of steps in the HAZOP methodology are typically these:[5][9]

Risk ranking matrix

The adjacent Table 3 provides an example of a typical risk ranking matrix defining four levels of risk:

As shown in Table 3, each of the four levels of risk are defined by their severity and likelihood of occurrence as identified and recorded during the step-by-step HAZOP methodology. Table 3 is merely an example matrix and the HAZOP team may agree upon the use of a variation of Table 3 that uses more risk levels as well as different names and different action requirements for each level. References

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Pages using ISBN magic links

- Articles for deletion November

- CZ Live

- Engineering Workgroup

- Chemistry Workgroup

- Chemical Engineering Subgroup

- Emergency management Subgroup

- Environmental Engineering Subgroup

- Articles written in American English

- All Content

- Engineering Content

- Chemistry Content

- Chemical Engineering tag

- Emergency management tag

- Environmental Engineering tag