Hydrodynamic testing

- See also: Hydronuclear testing

Hydrodynamic testing uses extremely high speed instrumentation, often with X-rays or protons, to determine fluid dynamics of what happens inside an explosive reaction. [1] It is not limited to explosive speeds; instrumenting the fluid dynamic behavior of models is useful in ship design, weather analysis, and other fields.[2]

Explosive range

It may use X-ray, proton, neutron, or other flash radiography to measure, in microseconds or less, the explosive compression of a fissionable material simulant. Depleted uranium, for example, has the same physical properties as enriched uranium, and is similar to plutonium.

| Hydronuclear testing

A related technique, hydronuclear testing, does actually have a nuclear reactions, although very small in yield (e.g., kilograms to low tons). The lowest range are unlikely to be detected, at least by seismic methods. |

These methods, however, are by no means limited to nuclear weapons. They can be used for studying explosively driven metal forming, such as metal welding. They also can be used to study the characteristics of new types of explosives.

Test operations

Conducting these tests require a diverse range of skills including physics, photography, and materials science. The test specialists, in the U.S., are informally called "ramrods". [3]

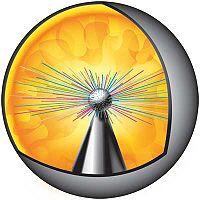

Pin dome

Not all testing methods are photographic. The pin dome method puts conductive pins into a sphere to be imploded, which sense the movement of the shock wave toward the center.

Water

References

- ↑ Pike, John. Nuclear Weapon Hydrodynamic Testing. Globalsecurity.org. Retrieved on 2010-05-16.

- ↑ Hydrodynamic Testing Facilities Database, U.S. Department of Energy

- ↑ "Ramrods Shepherd Hydrodynamic Tests", Science and Technology Review, Lawrence Livermore National Laboratory, September 2007